Tower Bridge is one of five London bridges owned and maintained by Bridge House Estates, a charitable trust overseen by the City of London Corporation. Opening and closing of the bascules is undertaken by technical staff directly employed by the Tower Bridge organisation, led by the head of Tower Bridge. There is no longer a “Master” of the bridge. The head of Tower Bridge reports to the head of the City’s Directorate of Open Spaces.

Technicians also undertake some maintenance activities, but much of the necessary maintenance is performed by contractors. Engineering oversight is by “the City Engineer” and his team, employed by the City’s Department of the Built Environment.

Tower Bridge will soon have a close subterranean neighbour, the Thames Tideway Tunnel. While researching for the Haynes Tower Bridge Operations Manual I discovered that a September 2013 study undertaken by AECOM and commissioned by Tideway into the impact of tunnelling on Tower Bridge was flawed and that, accordingly, its conclusions should not be relied upon.

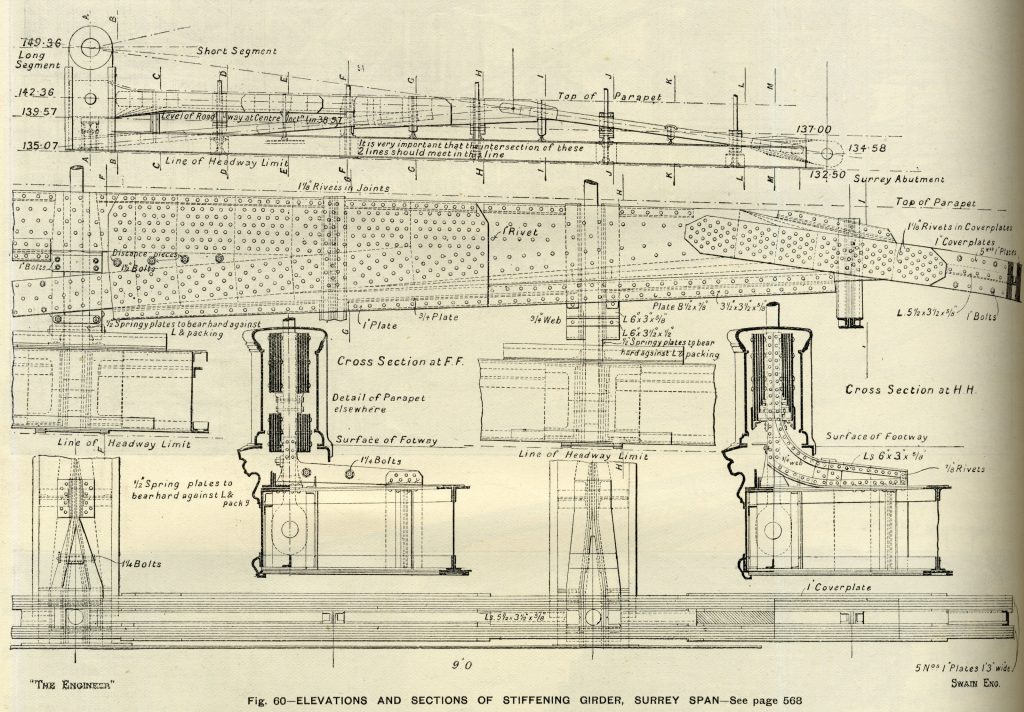

The computer model used in the study omitted two huge structural members (known as the stiffening girders), each weighing some 100 tonnes, 100ft in length and carrying substantial compressive stress. These members are hidden within the parapets of the Surrey suspension bridge below the Surrey short chains. (They were also overlooked in a study undertaken by Mott, Hay and Anderson in the 1940s.)

A conclusion of the study was that the two piers of the bridge will rotate towards each other. My concerns about this were that:

- There are four rocker assemblies atop the shoreward steel columns of the main towers. As originally designed, the rockers allowed the bridge to move to accommodate thermal expansion and contraction, and dynamic loading. If these rockers were still working, the small rotation of the piers as the result of tunnelling could be taken by the bridge “in its stride”. Unfortunately, they are seized (and have been since the 1940s I believe). Rotation of the piers will increase the stresses on the rocker assemblies. It is possible that some part of one or more of the four rocker assemblies will fracture, enabling the bridge to relieve itself (probably asymmetrically) of the substantial increased tension in the main long chains. Damage to the rocker assemblies would not necessarily endanger the structural integrity of the bridge, but it would be difficult and expensive to repair.

- I suspect that some, many or all of the pinned joints in the suspension bridge end-to-end structure are also seized, so the bridge can no longer articulate.

- Catenary wire “suspension bridges” were installed in 1960 to relieve the high-level walkways of the circa 80 ton weight of each high-level tie. A good solution to protect the walkways, but one which causes a circa 400 ton horizontal force to act at the top of each main tower – currently resisted by the seized rockers, I suspect.

- The degree of rotation of the piers due to the tunnelling forecast by the AECOM study is just an estimate; it might be less, or more – it’s just a model.

- When the piers rotate: more stress will be placed on the seized rockers by the stretching of the main chains of the suspension bridge. The AECOM study concludes that the high-level ties will reduce in length as the tops of the towers move closer together, and that the bridge will hog – implying no additional tension in the long and short chains. This cannot be correct as the stiffening girders prevent hogging, at least on the Surrey side.

- The additional stress in the main chains due to their stretching must be modelled and calculated to prove beyond doubt that these members will not be overstressed.

- Then again, perhaps the tops of the towers will not move at all – everything at the top of the bridge being held “as is” by the seized rockers, the horizontal ties and the chains. In this scenario, the main columns would have to bend, increasing substantially the bending moments in the columns and possibly causing cracking in the masonry cladding. It’s likely that all of these effects will happen to some degree.

- Should the rockers be freed up before the tunnel arrives? Tunnelling would probably have to be delayed, but it sounds like a good plan to handle the pier rotation. But would the horizontal pull of the catenary cables then start to rotate the rotating piers still further?

Over a period of some years I have expressed my concerns to the Tower Bridge organisation, City of London officers, engineers, surveyors, City of London departmental managers, the Bridge House Estates trust, the chair and secretary of the City’s Audit and Risk Management Committee, to AECOM directors and engineers, and to the Tideway organisation. I’m sad that many of these emails and letters were unanswered and I did not receive assurance that my concerns were being listened to and acted upon.

However, in August 2019 I did receive an assurance from the Tideway chief technical officer that there is a developed, construction-phase analysis of the structure which takes appropriate account of the issues raised, including the calculated loadings and bearing pressures, and the construction of the stiffening girders, land ties, catenary cables and footpath. So perhaps my extensive communication with those responsible for the safeguarding of the bridge had a positive effect. I hope so. My confidence in those responsible for safeguarding the bridge has certainly increased. But it remains to be seen whether the tunnel causes the bridge any problems.